AP 190

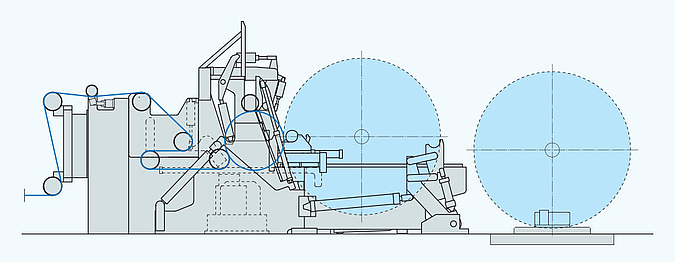

Fully automatic non-stop “pope” type winder for paper & board and for aseptic packaging

The automatic winder AP190 (the “pope”) is suitable to wind a large variety of coated or uncoated papers and boards as well as complex material for aseptic packaging, in a reliable and highly efficient manner. The AP190 is designed to be installed at the outlet of operating machines of any kind such as rotary printing machines, coating or extrusion coating lines, etc. The AP190 is suitable for working width from 1000 to 2500 mm and for winding diameter up to 1900 mm. For larger diameters, up to 2500 mm and more, other models are available (AP220, AP250 and others), For even larger working width and/or diameter, special versions can be delivered on Customer’s request.

Highest Reliability for large rolls

- Roll weight up to 12000 kg

- Full speed non-stop splice up to 800 m/min

- Automatic closure of finished roll

- Automatic unloading of finished roll

- Automatic shaft extraction and core loading

- Optional slitting and trimming unit (up to 2 slits + trims are possible directly at the winding)

Perfection in Converting Paper and Board and Aseptic Packaging Material

Thanks to the unique “plow knife” cutting system, the AP190 guarantees outstanding and consistent splice reliability while the sensitive pressure control ensures very high roll quality even with high grade paperboard

TECHNICAL DATA

| PRODUCT TO BE PROCESSED | SPEED | WEB WIDTH | DIAMETER OF FINISHED ROLLS |

|---|---|---|---|

| Complex material for aseptic packaging for liquid food | up to 800 m/min | up to 2,000 mm | up to 1,900 mm |

| General purpose papers and paperboards | up to 800 m/min | up to 2,000 mm | up to 1,900 mm |

| Packaging paper & paperboard | up to 800 m/min | up to 2,000 mm | up to 1,900 mm |