DOC 120

High-speed inspection rewinder to repair finished rolls of paper and board

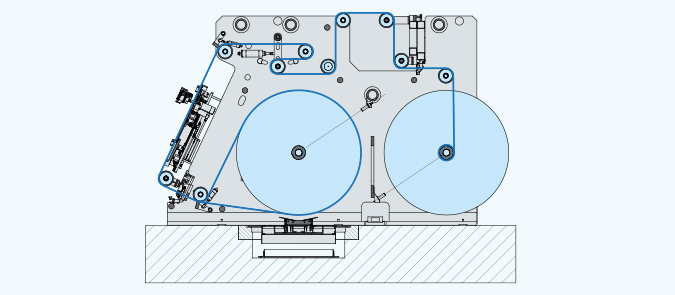

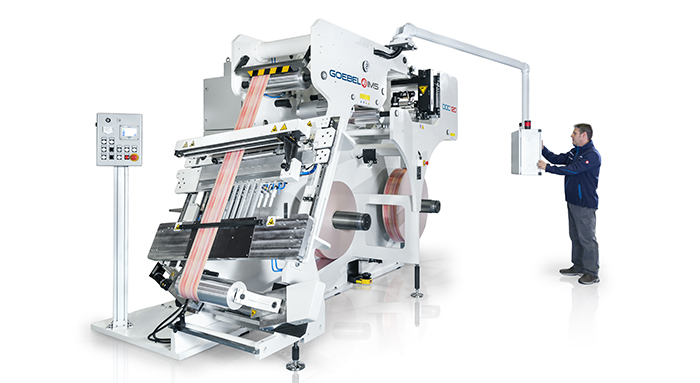

The DOC120 is a narrow, single-frame inspection and salvage rewinder with overhanging shafts for roll gripping and lifting table at one end for loading/unloading purposes. The machine offers the best solution for converters who need to repair damaged or telescoped rolls, or build-up larger rolls from smaller ones, or remove scrap or simply inspect the quality of their finished rolls. The DOC 120 is suitable to work with all types of paper and board, either plain or coated, but it is definitely perfect when used for printed materials, such as the aseptic packaging materials, where matching the printed pattern in a perfect way is of vital importance. The DOC120 can of course wind in both directions (forward and backwards) and each of the unwind/rewind units can run clockwise or counterclockwise, thus giving maximum flexibility to the operator for any kind of repairing job.

The machines can also be equipped with different options:

- Trimming knives

- Dedicated thermo-welding splice table with adjustable incline specifically designed for aseptic packaging or any other type of customised splice unit.

- Inspection unit with cameras or other customised devices.

- Two separate edge tracking devices for ensuring perfectly straight winding.

TECHNICAL DATA

| PRODUCT TO BE PROCESSED | SPEED | WEB WIDTH | DIAMETER OF FINISHED ROLLS |

|---|---|---|---|

| Complex material for aseptic packaging for liquid food | up to 1,000 m/min | up to 500 mm | up to 1,200 mm |

| General purpose papers and paperboards | up to 1,000 m/min | up to 500 mm | up to 1,200 mm |

| Packaging paper & paperboard | up to 1,000 m/min | up to 500 mm | up to 1,200 mm |