FLEXISLIT

Maximum productivity for the flexible packaging industry

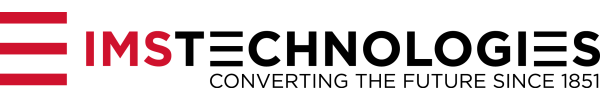

The FLEXISLIT is the answer to the expectation of the most demanding film manufacturers and converters in the flexible packaging industry. It features a versatile and modular high-end dual shaft or turret slitter that can be easily tailored according to the customer’s needs.

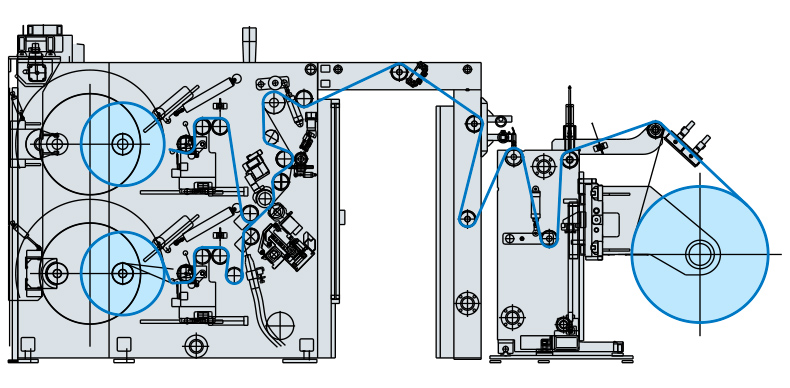

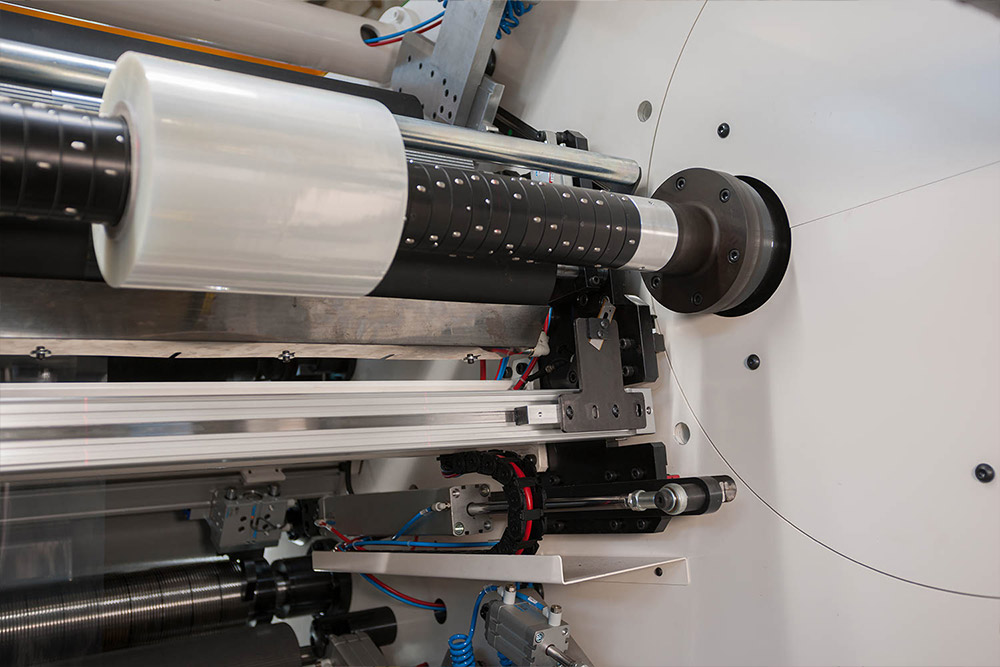

With a speed up to 800 m/mm, the FLEXISLIT ensures a high quality of the finished reels while increasing drastically the productivity and efficiency of the slitting operation. The winding quality of the finished reels is obtained thanks to the new friction differential shafts, working in a closed loop control, and the precise pressure of the linear and independent lay-on rollers.

This design also allows saving substantial machine downtime, by closing automatically the finished reels tails and sticking the strips on the new cores within the automatic cycle. Automation can be pushed even further, by choosing special uploading devices allowing the automatic insertion and positioning of the cores on the shafts.

COMPACT AND ROBUST DESIGN

-

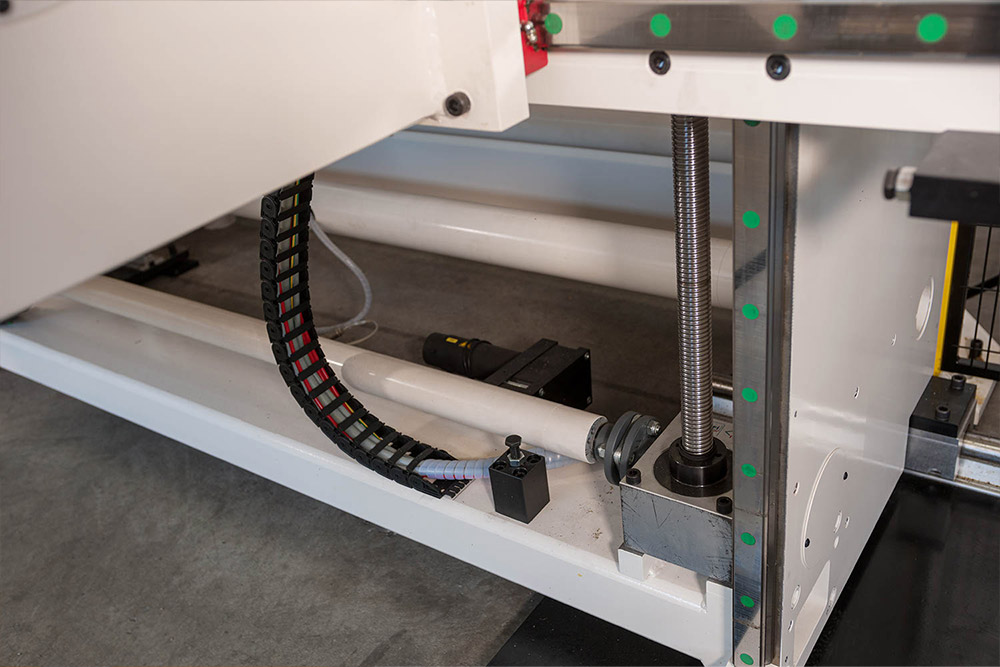

Compact and robust design, minimizing the footprint requirements

- Working widths up to 1,650mm

- High speeds up to 800 m/min

- Dual slitting method – razor blades and circular knives

- Rewinding on newly designed friction shafts or torque controlled air expanding shafts

- Linear and independent pressure rollers

- New and ergonomic industrial design

- Full compliance with the strictest safety standards

- Oil free design

FLEXISLIT Series is the top level of automated slitters for the flexible packaging industry.

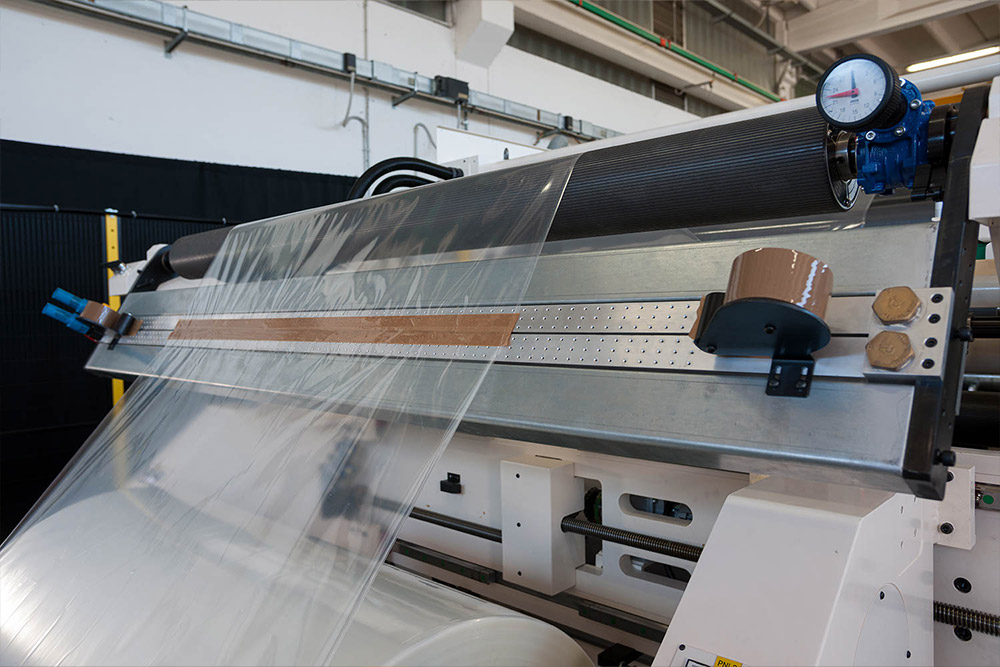

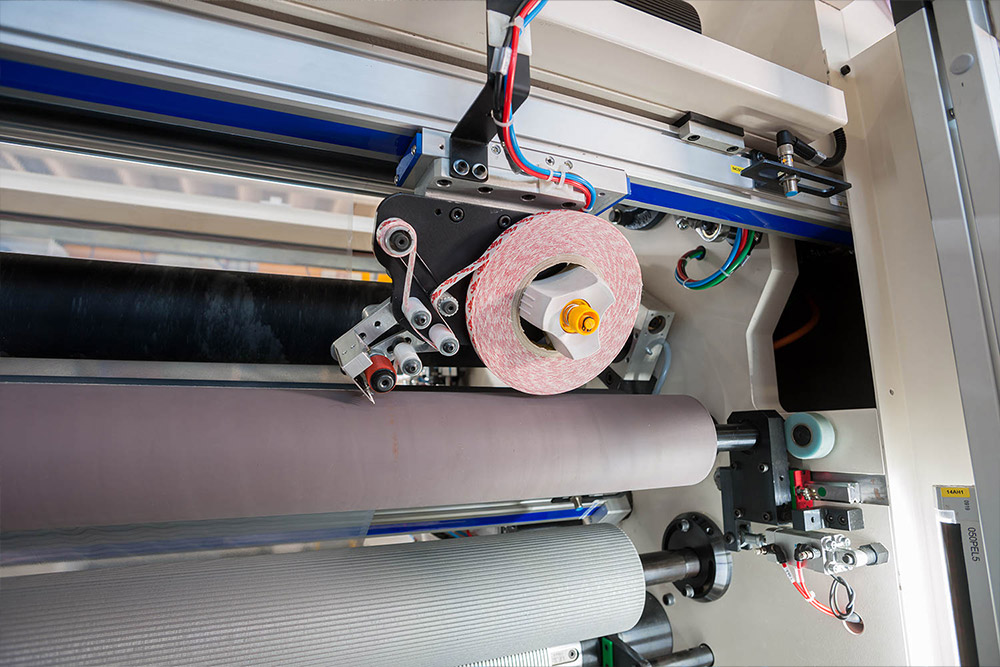

The whole procedure involving the crosscut and the turret cycle sequence makes it possible to close the tails of the reels automatically and prepare the cores automatically, thanks to a cross-web tape dispenser assembly.

Several closing tails processes – either by double sided tape on the inside of the web or by an external tape placed manually on the outside of the roll- can be installed on the slitter, making it a unique solution for delivering finished products.

The other special features (options or base scope) are the automatic positioning of the cores by a special automatic pusher and the possibility to include in the supply an automatic cores buffer/loader, which in combination with the unloader, the SC device, places the cores onto the shafts during the cycle.

The above-mentioned features maximise the machine uptime, while minimizing the operator intervention.

This machine configuration is best suitable for integration with an end-of-line module for the packing and palletizing of the finished reels.

TECHNICAL DATA

| Mother reel web width up to: | 1750 mm // 69” |

|---|---|

| Mother reel diameter: | Max. 1270 mm // 50” Min. 450 mm // 17.7” (automatic lifting) |

| Mother reel weight up to: | 2000 kg/td> |

| Maximum diameter of finished reels: | 600 mm // 23.6” |

| Minimum slitting width: | 80 mm // 3.2” for 6" shafts 40 mm // 1.6” for 3" shafts |

| Speed up to: | 800 m/min // 2625 ft/min |

| Web direction: | Right-side or Left-side |

| Drives, motors, PLS, touch panel | Siemens |

* The above data refer to standard models, technical modifications are available on request