RB-4

Dual-shaft turret slitter rewinder for quick cycle times

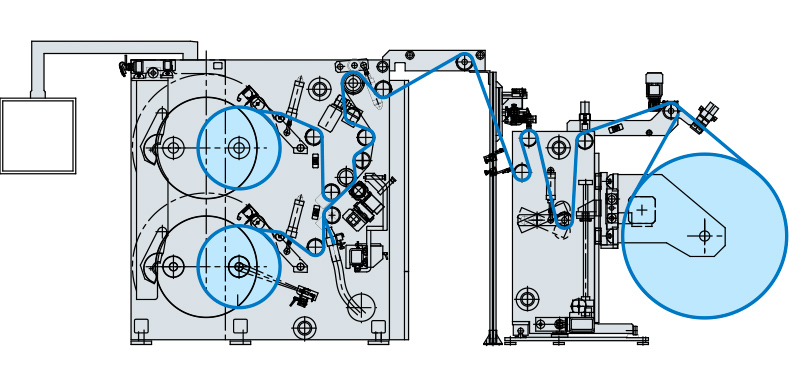

This centre-driven slitter rewinder is designed for film manufacturers and converters who need to produce several finished reels of relatively small diameters.

The RB 4 drastically reduces the cycle downtime of a dual shaft machine as it allows the operator to place the new cores on the idle shafts, with the aid of a precision laser pointer, as the machine is rewinding on the other shafts.

Automatic turret cycle

When the rolls reach the set diameter or length, the machine stops and the automatic turreting sequence starts.

At this point, with the machine is in production again, the operator can unload the finished rolls from the shaft which is now in stand-by position; and with the laser pointer indicating the precise pre-set slitting positions, the operator can load the cores on this shaft in preparation for the following cycle.

Independent unwinder with integrated functions

The unwinder is an independent unit, connected to the machine body through the overhead web path bridge. It can be equipped with extra devices which give added value to the working process and finished product: splicing table, flag detector (for handling waste spans of the parent roll),register mark counter (for counting the printing repeats), and others.

TECHNICAL DATA

| Mother reel web width up to: | 1750 mm // 69” |

|---|---|

| Mother reel diameter: | Max. 1270 mm // 50” Min. 450 mm // 17.7” (automatic lifting) |

| Mother reel weight up to: | 2000 kg/td> |

| Maximum diameter of finished reels: | 600 mm // 23.6” for RB 4 (Turret) |

| Minimum slitting width: | 80 mm // 3.2” for 6" shafts 40 mm // 1.6” for 3" shafts |

| Speed up to: | 600 m/min // 1.968,5 ft/min |

| Web direction: | Right-side or Left-side |

| Drives, motors, PLS, touch panel | Siemens |

* The above data refer to standard models, technical modifications are available on request