TR-2

Heavy-duty dual-shaft slitter rewinder

This sturdy machine is recommended either when there is a need to rewind and handle extremely large and heavy rolls, or when the materials to handle require particular accuracy and sophisticated slitting technology, such as paper products or clear-on-clear label stock for example.

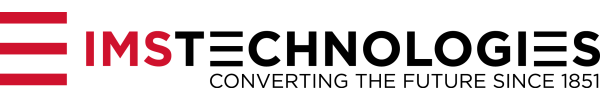

Linear Track technology – The entire process area of the machine is mounted on additional frames that move backwards on linear guides during the rewinding procedure, therefore minimizing the distance between the slitting and the rewinding point and maintaining it constant throughout the winding cycle.

S-Wrap draw roller for handling delicate products

The main “S”-wrap draw roller guarantees a very wide wrap angle around it; together with the nip roller, it guarantees the most stable and precise handling of the web material at high speeds.

When processing delicate materials, like cold-seal laminates, the S-wrap manages to pull the material without the nip roller, hence protecting the product.

Ultimate lay-on roller technology

This configuration mounts compact and ergonomic lay-on rollers, even when converting large rolls, to always maintain contact with the winding rolls at the same point and moving back on the linear guides with the rest of the frames as the diameter increases.

For substrates with large gauge variation it is possible to order independent lay on rollers of specific dimensions.

Faster production set up

The mechanical design of the machine allows the operator to thread the slit strips much faster and save time during job changes or simply when there are different cycles within the same job.

TECHNICAL DATA

| Mother reel web width up to: | 1750 mm // 69” |

|---|---|

| Mother reel diameter: | Max. 1270 mm // 50” Min. 450 mm // 17.7” (automatic lifting) |

| Mother reel weight up to: | 3000 kg/td> |

| Maximum diameter of finished reels: | 800 mm // 31.5” |

| Minimum slitting width: | 80 mm // 3.2” for 6" shafts 40 mm // 1.6” for 3" shafts |

| Speed up to: | 800 m/min // 2625 ft/min |

| Web direction: | Right-side or Left-side |

| Drives, motors, PLS, touch panel | Siemens |

* The above data refer to standard models, technical modifications are available on request