VIS 100

Highly automated doctoring machine for jumbo rolls

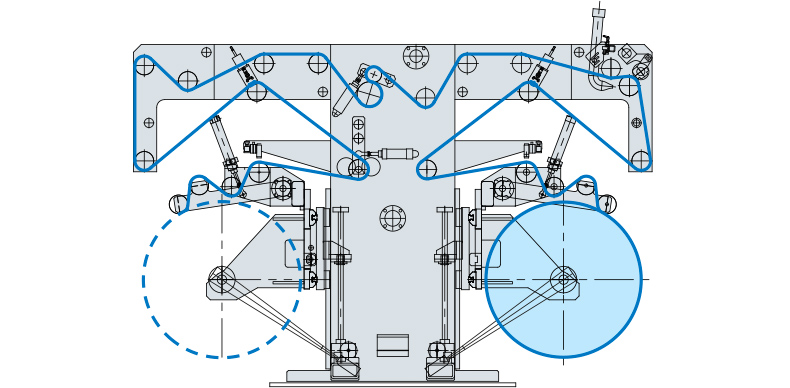

The VIS 100 is the ideal machine for inspecting and cleaning jumbo rolls soon after they have been printed. In this way, once they have been laminated or metalized, the rolls reach the final slitting process without printing defects, thus avoiding the costly waste of material already treated.

Thanks to the combined action of the splicing table and the waste winder, the operator can quickly recover the roll, reproducing it without defects and with the web held under perfect tension.

Optimum tension control, at all stages of the process

The unwinding and rewinding web tensions are controlled by dancer rollers which are loaded by means of high-sensitivity pneumatic cylinders, in order to maintain perfect web tension in both running directions.

Automated error detection through an integrated video system

The integration of 100% inspection system allows to find printing defects (such as colour variations, blurs and off-register) in real time and at maximum production speed. Once a defect is discovered, the VIS 100 stops, reverses its running direction and rewinds until the beginning of the defective web span reaches the splicing table.

TECHNICAL DATA

| Maximum roll width | 1,200 mm > 2,500 mm |

|---|---|

| Maximum roll diameter | 1,000 mm |

| Maximum roll weight | 2,000 kg |

| Maximum production speed | 600 m/min. |

| Machine direction | Bidirectional |

* The above data refer to standard models, technical modifications are available on request