VIS 80

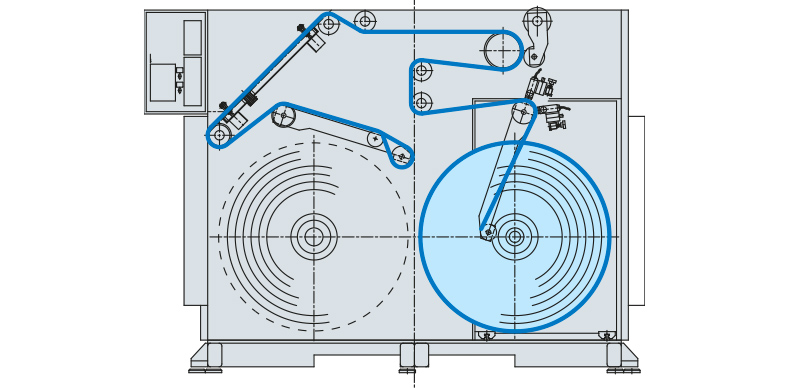

Bidirectional doctoring machine for finished rolls

This bidirectional doctoring machine is versatile and compact and designed for correcting any web misalignment and removing faulty printed spans. With the aid of the splicing table equipped with web stopper bars, the operator can clear the reels in order to deliver only a top quality product. The VIS60/80 can be integrated with several auxiliary equipments, such as stroboscopic lights or videocamera for web inspection, and its layout and functionality can be completely configured.

Special applications in white chamber

A special version of VIS80 is available for white chamber, completely chrome plated without hydraulics. This allows for the production of top quality rolls, completely free of defects and in full compliance with the most recent regulations for safe food pharmaceuticals processing.

Automatic detection of defects through workflow datalink

If the printing defects in the roll were recorded during the previous process, the system is capable of bringing the beginning of the defective web span onto the splicing table in order to facilitate its recovery by the operator.

TECHNICAL DATA

| Maximum roll width | 500 mm > 800 mm |

|---|---|

| Maximum roll diameter | 800 mm |

| Maximum roll weight | 400 kg |

| Maximum production speed | 600 m/min. |

| Machine direction | Bidirectional |

* The above data refer to standard models, technical modifications are available on request