Lynex S

100% Print Inspection For Narrow Web Presses.

The Guarantee for Total Quality Control

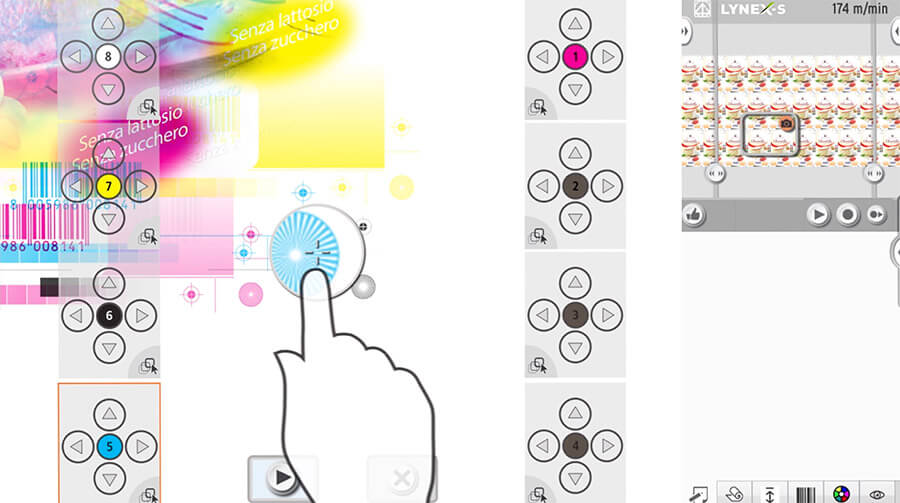

LYNEX-S is a 100% print inspection developed to assure the total quality control during the printing process. The continuous inspection of the entire print repeat, with programmable sensitivities, allows the automatic detection of all print or substrate defects and a real time evaluation of the production.

The system provides this data in roll maps and generates production reports for subsequent analysis and workflow use.

The immediate warning, when a flaw is detected, guarantees the elimination of defective material which optimizes your process and avoids claims.

The modular architecture, combined with powerful hardware and dedicated algorithms for image processing, make the LYNEX-S a flexible and easy to use instrument for inspection on gravure, flexo, offset and digital presses. It can be expanded with the addition of numerous options such as: semi or automatic register, color monitoring, bar code verification, print elongation, waste tracking.

LYNEX-S can operate as stand-alone module in multiple processes, as a print or substrate inspection device, or in combination with the MATRIX Plus.