RA 2

The slitter rewinder machine for technical and special paper

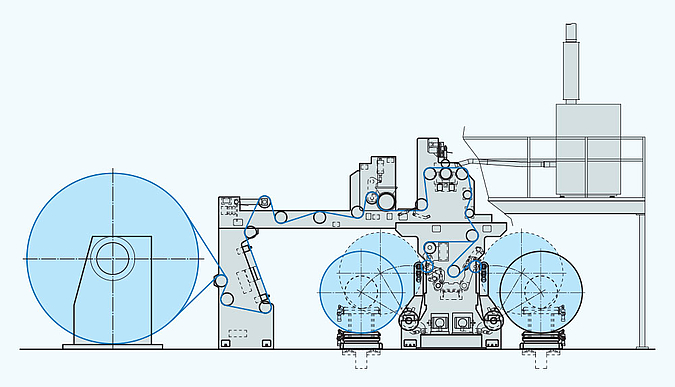

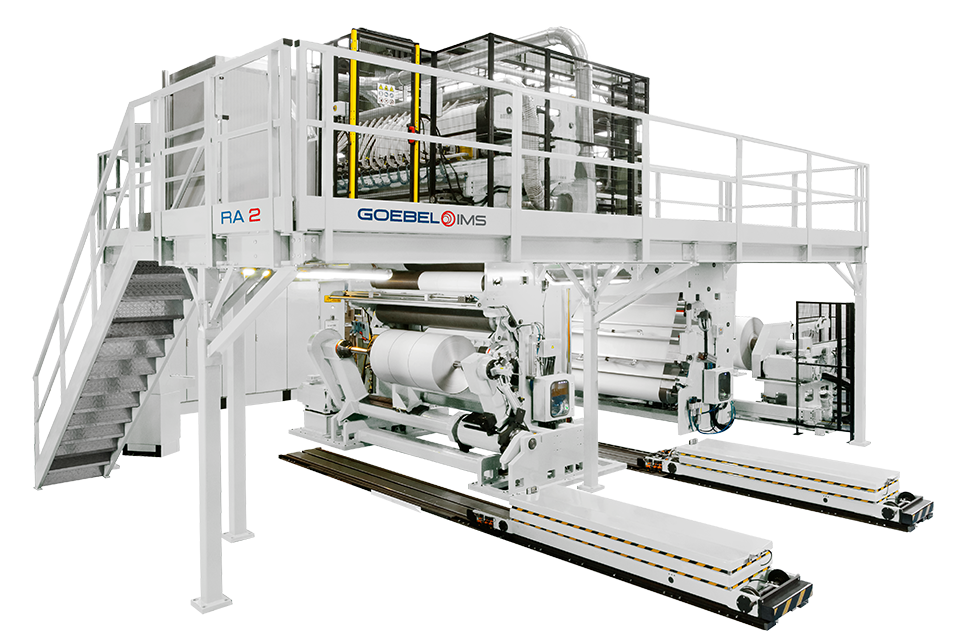

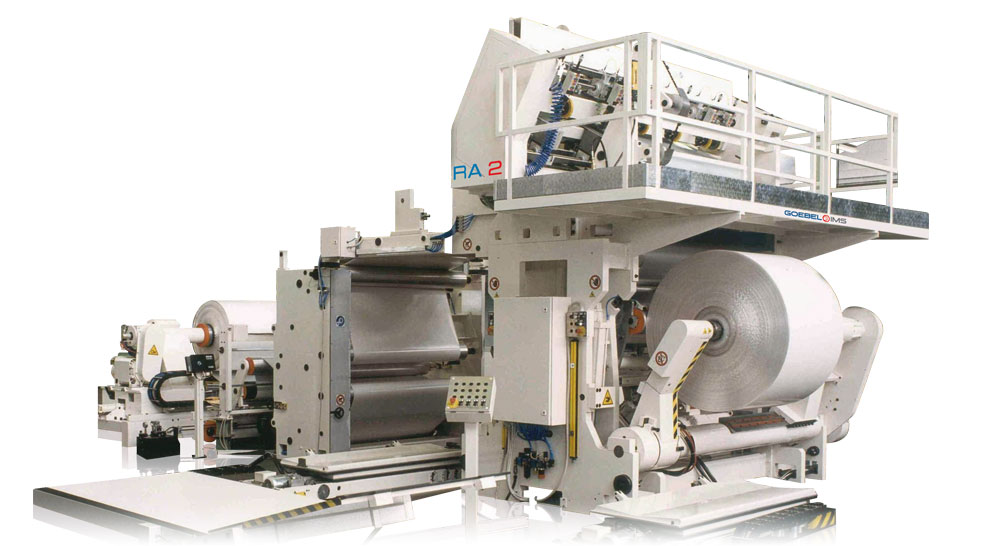

The RA 2 is a center-driven slitter rewinder with two independent single-shaft center rewinding stations with idle lay-on rollers. It is a very popular machine for converting fine and delicate papers. Typical applications of the RA 2 are thermal paper, carbonless copy paper, coated paper, release paper, inkjet paper and others. The pressure of the lay-on rollers can be adjusted very precisely through a pneumatic system to ensure careful winding for materials with delicate surfaces. The rewinding technology of the RA 2 keeps a constant force in the nip throughout the entire process, guaranteeing the output of compact rolls at high speeds of up to 1,500 m/min while avoiding any damage to the surface of the paper.

Discover the advantages of this slitter rewinder:

- Unique winding concept for pressure sensitive or coated materials

- Guaranteed output of compact rolls at high speeds of up to 1,500 m/min

- Minimum slitting width of 80 mm with a maximum diameter of the finished rolls as large as 1,500 mm

- Low inertia and unaffected web tension thanks to idle rolls made of carbon fibers

- Fast reel-change and easy new core loading

- High efficiency also with applications requiring frequent changing of slit sizes and format changeovers

- Optional downstream automation including reel turning, labelling and palletizing

With its unique double single-shaft winding concept it combines the advantages of the single shaft concept, that is a fast reel-change and easy new core loading, with the possibility to reach very wide web width far beyond the possibilities of a traditional single shaft slitter. The machine comes with an automatic unloading system through which finished rolls are deposited on driven carts. These are used to pull out the rolls from the winding shafts and to deliver them on the side of the machine. The slitting unit of the RA 2 features full automatic positioning of the knives which ensures a high level of efficiency with applications that require frequent changing of the slit sizes. Additional options for specific customer requirements are customized splice tables as well as automatic unloading and reel transport solutions. Exceeding electrical energy is reused in the system which makes the RA 2 an energy-efficient solution while guaranteeing excellent quality and highest productivity for converting fine and delicate papers.

The RA 2 is suitable for the following industrial applications, among many others

Manufacturers and converter of the technical and specialty paper converting industries rely on the RA 2. The RA 2 processes thermal paper, siliconized papers, coated separator papers, carbonless copy paper, inkjet papers and more.

Two RA 2 slitter rewinders used at Gold Huasheng Paper Mill

The Chinese company Gold Huasheng Paper Mill received two RA 2 slitter rewinders from GOEBEL IMS. The two 2,300 mm wide machines were successfully delivered and commissioned to the industrial town of Suzhou, China. Gold Huasheng Paper Mill, part of the Sino-Indonesian paper group APP, will use the two RA 2’s for slitting thermal paper. The commissioning of the RA 2’s went perfectly since the machines were fully tested prior to delivery. By setting up all machines entirely and employing test runs, GOEBEL IMS ensures a “vertical start up” process for the machinery once delivered to the customer. Discover how the RA 2 can help you make your converting process more efficient and productive. Contact our experts and ask for your customized RA 2 slitting and winding solution.

TECHNICAL DATA

| PRODUCT TO BE PROCESSED | SPEED | WEB WIDTH | DIAMETER OF FINISHED ROLLS |

|---|---|---|---|

| Decor paper | up to 1,000 m/min | up to 2,500 mm | up to 1,200 mm |

| Ink-jet paper | up to 1,000 m/min | up to 2,500 mm | up to 1,200 mm |

| Carbonless copy paper | up to 1,000 m/min | up to 2,500 mm | up to 1,200 mm |

| Security paper | up to 1,000 m/min | up to 2,500 mm | up to 1,200 mm | Papers with delicate coating | up to 1,000 m/min | up to 2,500 mm | up to 1,200 mm |