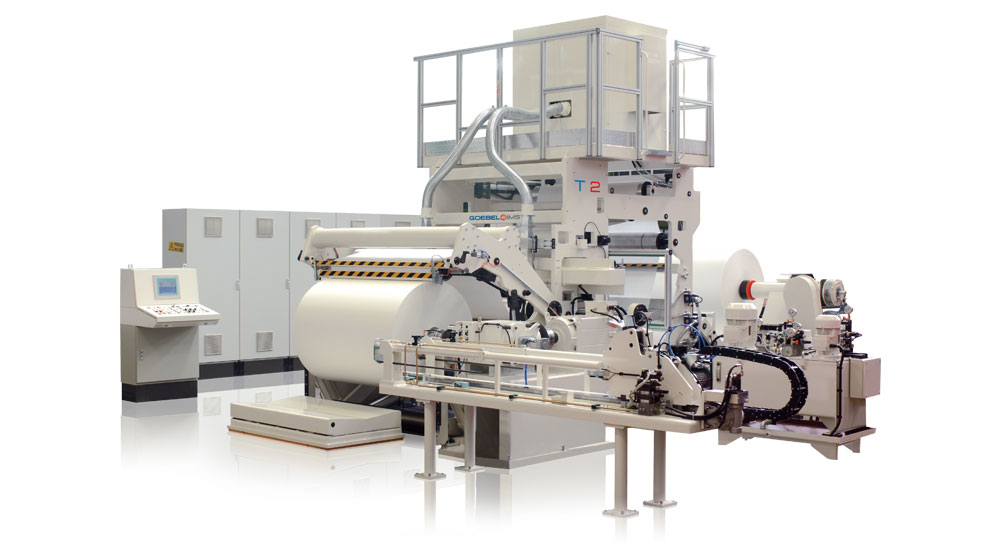

T 2

High productivity, top level, fast, efficient and versatile single-shaft centre-driven slitter, for paper, board and aseptic packaging material

Maximum productivity and flexibility

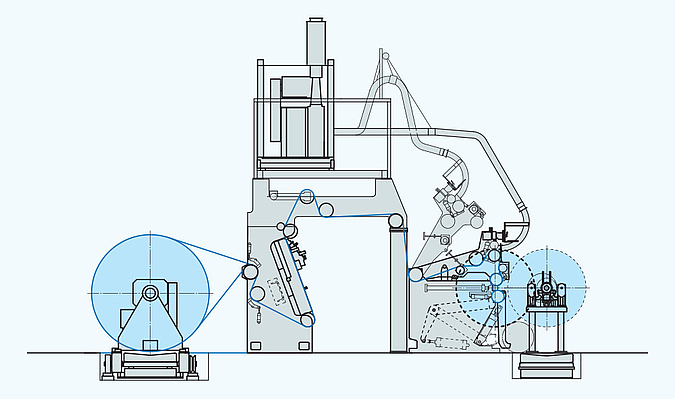

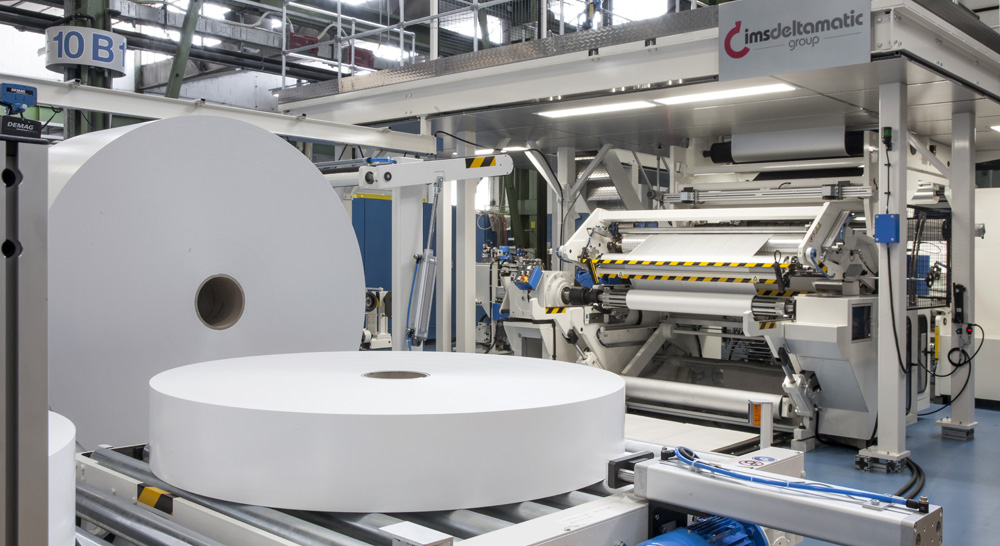

Sturdy, operator friendly, flexible and highly productive single shaft, centre-driven slitter rewinder equipped with an idle lay-on roller. The T2 is suitable for a large variety of papers and boards either plain or coated as well as aseptic packaging materials.

The T2 offers top winding quality and high speed. The web width can reach up to 2,400 mm, the max rewind diameter is 1,800 mm and the max unwind diameter can be even more than 2,000 mm. The unique web way in the slitting section, which is the result of our long experience, guarantees outstanding roll separation, even with narrow slits down to 50 mm. The T2 reaches an operating speed of up to 1,200 m/min.

The T2 represents a long-lasting success story: the first units of this model have been introduced to the market as many as 60 years ago and, since then, more than 120 T2’s have been installed everywhere in the world while we have continuously improved it during the years.

Additional features and modular configuration to meet customer needs

Thanks to its ergonomic and flexible design, the T2 can be adapted to individual customer needs and specific requirements with a large choice of options such as:

- Fully-automatic reel and shaft handling equipment and conveyor system for improved unloading and automatic removal of the finished rolls, meant to reduce the stop time and improve the efficiency of the production process.

- Oil-free version (no hydraulic functions), specially designed for Customers working in the food industry where environmental cleanliness is paramount.

- Customized splice table including a special version with thermo-welding process, designed specifically for complex materials for liquid food packaging.

- Fully automatic knife positioning system.

- Double unwinder for speeding up the replacement of the mother roll.

- Two edge control systems for ensuring extremely precise alignment of the slit to the print.

- Lower lay-on roller for winding large reels on small cores.

- Bi-directional function for repairing telescoped or damaged rolls as well as detecting defects.

TECHNICAL DATA

| PRODUCT TO BE PROCESSED | SPEED | WEB WIDTH | DIAMETER OF FINISHED ROLLS |

|---|---|---|---|

| Complex material for aseptic packaging for liquid food | up to 1,200 m/min | up to 1,650 mm | up to 1,800 mm |

| Decor paper | up to 1,000 m/min | up to 2,000 mm | up to 1,800 mm |

| Ink-jet paper | up to 1,000 m/min | up to 2,000 mm | up to 1,800 mm |

| Carbonless copy paper | up to 1,000 m/min | up to 2,000 mm | up to 1,800 mm |

| Security paper | up to 1,000 m/min | up to 2,000 mm | up to 1,800 mm |

| Thermal paper | up to 1,000 m/min | up to 2,000 mm | up to 1,800 mm |

| Papers with delicate coating | up to 1,000 m/min | up to 2,400 mm | up to 2,000 mm |

| Filter paper for automotive | up to 800 m/min | up to 2,200 mm | up to 1,270 mm |

| Thick, low density papers | up to 800 m/min | up to 2,400 mm | up to 1,270 mm |

| Packaging paper & paperboard | up to 1,000 m/min | up to 2,400 mm | up to 2,000 mm | General purpose papers and paperboards | up to 1,000 m/min | up to 2,000 mm | up to 1,800 mm |

| Silicon-coated paper | up to 800 m/min | up to 2,000 mm | up to 1,500 mm |